Blum-Novotest grows its own to meet surge in adaptive machining

The growth in sub-contractors and OEMs looking at in-machine measurement has seen a world leader turn to apprenticeships to help it meet demand for its technology.

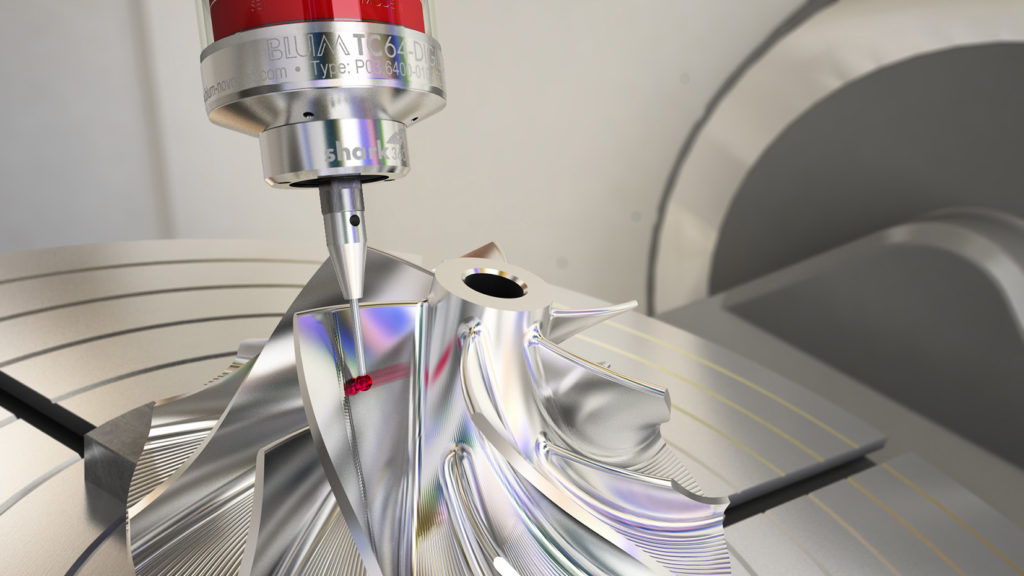

Blum-Novotest, which offers laser control, tool setting probes, workpiece probes, roughness/bore gauges and the new DIIGLOG touch probes, has taken on Jack Perkins as a trainee machinist.

It is working with In-Comm Training to help it deliver the apprenticeship, with the 20-year-old initially spending four days per week at the state-of-the-art Aldridge Training Academy that has access to nearly £600,000 of CNC machines.

He has just started his second year, which will see more time spent with the East Staffordshire firm’s in-house engineers supporting them on installation, servicing and maintenance projects.

“The way manufacturers measure workpieces is changing and there is a definite shift to embrace the latest in-machine metrology solutions, meaning our engineers are very busy,” explained David Mold, Managing Director at Blum-Novotest.

“We had predicted this growth and decided the best way to grow our team was by investing in an apprentice that we could shape in the Blum methodology and product offer.”

He continued: “In-Comm is the first training provider we have worked with and has been excellent from start to finish, helping us with the recruitment of Jack and listening to our requirements so that the machinist course is tailored so we get an employee that can hit the ground running.

“The company also has some of the best machining facilities around, with the latest 5-Axis CNC machining centres readily available for our apprentice to learn on. We’ve even gone one stage further and donated some of our probes to go into the machines…these will benefit us directly, but also help other apprentices understand what adaptive machining is all about.”

Jack is doing very well on his apprenticeship and already impressed his peers by transferring the theory he has learned on to every day commercial projects.

Once he has completed the core training, he will be sent over to Blum-Novotest’s HQ in Germany for more detailed training on the full range of company products, including some new technology that has yet to be seen in industry.

David concluded: “We are currently looking at other upskilling opportunities that we can tap into from In-Comm as part of our commitment to remaining at the forefront of advanced manufacturing.

“Our membership of the In-Comm Training & Manufacturing Group has been really useful, especially being able to share information on projects and tapping into best practice processes employed by other member companies.”

For further information, please visit www.blum-novotest.com or follow @blumnovotestuk on twitter.