The Benefits of Automation and Robotics in UK Manufacturing

The global manufacturing sector has been revolutionised by technological advancements, with automation and robotics taking centre stage. The UK, known for its rich industrial history, has embraced these developments, making significant strides in integrating automated systems and robotics into its manufacturing processes. This evolution offers an array of benefits, ranging from enhanced productivity to improved quality control, positioning the UK as a competitive player in the global marketplace. As businesses face ever-growing pressure to reduce costs, increase efficiency, and meet the evolving demands of consumers, automation and robotics are emerging as indispensable tools for achieving these goals.

Browse our Robotics and Automation Courses here.

1. Increased Productivity and Efficiency

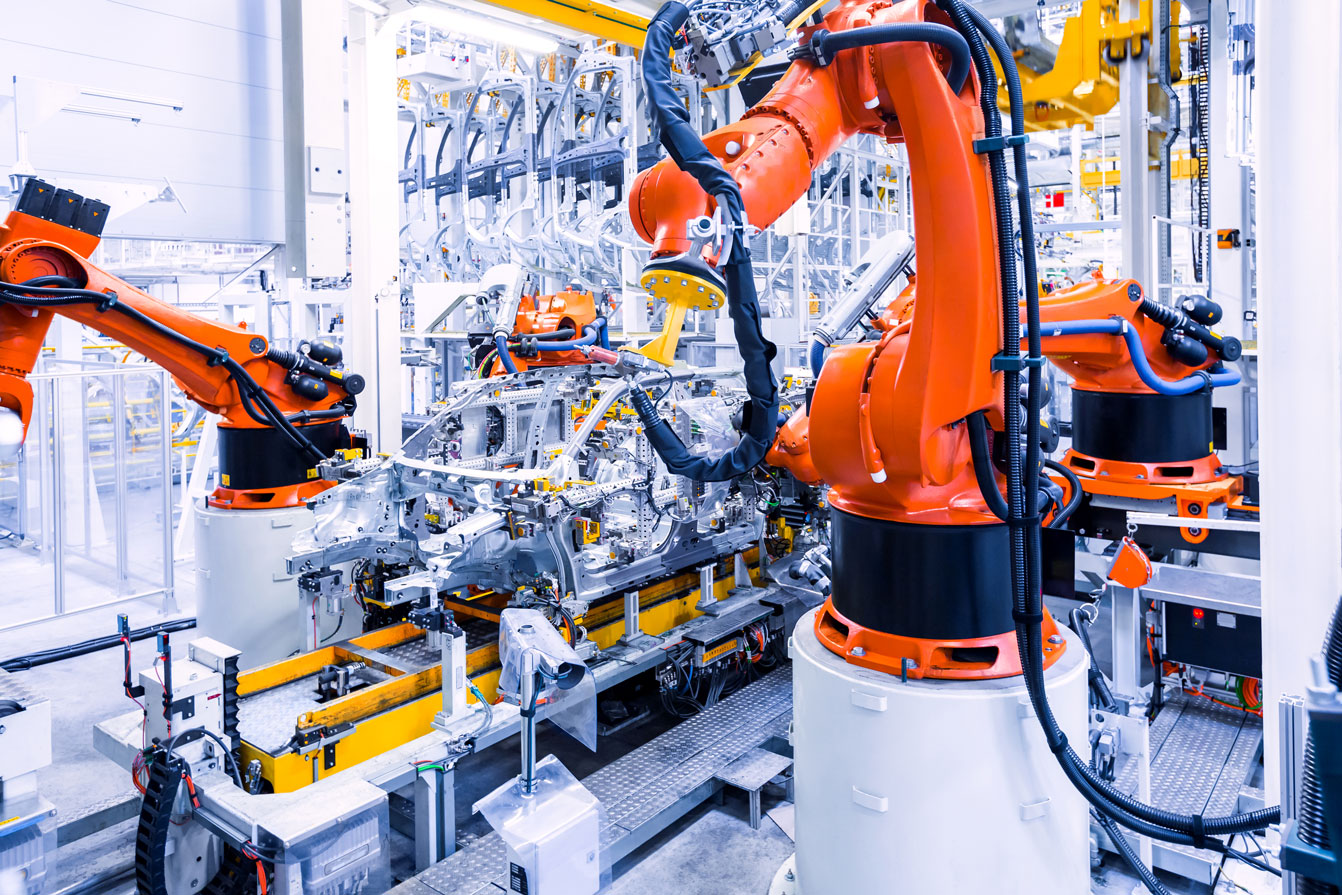

One of the most compelling advantages of automation and robotics in UK manufacturing is the ability to significantly increase productivity. Automated systems can run 24/7, dramatically boosting output levels. Robotics, in particular, can execute tasks with precision and speed that can far exceed human capabilities. This consistency not only accelerates production but also ensures that processes are carried out with minimal error, reducing costly downtime due to human mistakes.

For instance, in automotive manufacturing, the use of robotics for tasks such as assembly has slashed production times while simultaneously enhancing the quality of the finished product. As manufacturers continue to grapple with global competition and the need for cost-efficient production methods, the role of robotics in optimising time and resources has become even more critical.

2. Improved Quality and Precision

Automation and robotics are key to improving the overall quality of products. In industries such as aerospace, medical devices, and pharmaceuticals—where precision is paramount—the ability of robots to perform tasks to specific standards is invaluable. Automated systems are programmed to follow stringent quality control protocols, ensuring that each product is manufactured to the same high standard.

The consistency offered by robotics is particularly beneficial in sectors where human error could lead to significant issues, whether in terms of product recalls, customer dissatisfaction, or even regulatory non-compliance. By removing variability from the production process, automation leads to fewer defects, less rework, and higher levels of customer satisfaction.

For UK manufacturers looking to establish a reputation for high-quality goods, the use of automated systems and robotics can be a game-changer. The precision of robots, combined with the ability to consistently monitor and adjust production parameters, results in superior product quality that meets or exceeds industry standards.

3. Cost Reduction and Financial Savings

Although the initial investment in automation and robotics can be substantial, the long-term financial benefits far outweigh the costs. By automating routine tasks, businesses can reduce their reliance on human labour, which is often one of the highest expenses for manufacturers. While this does raise concerns about job displacement, it also presents opportunities to upskill the workforce, allowing employees to focus on higher-value tasks such as system oversight, maintenance, and innovation.

In addition to reducing labour costs, automation can also lead to savings in other areas, such as energy consumption and material waste. Automated systems are designed to optimise resource use, minimising waste and ensuring that energy is used more efficiently. Furthermore, the reduced error rate associated with automation means that less money is spent on reworking defective products, further cutting operational costs.

Over time, the investment in robotics pays off through reduced labour costs, increased productivity, and the ability to maintain a leaner operation. For UK manufacturers, this cost efficiency is a vital component of staying competitive in an increasingly globalised economy.

4. Enhanced Flexibility and Adaptability

One of the most remarkable aspects of automation and robotics is their ability to provide manufacturers with enhanced flexibility. Traditional manufacturing processes often involve rigid, inflexible systems that are costly and time-consuming to reconfigure. However, robots can be programmed and reprogrammed to handle different tasks, allowing manufacturers to quickly adapt to changes in product lines or customer demands.

This adaptability is especially important in industries like consumer electronics, where product life cycles are short, and demand can fluctuate rapidly. With robotics, UK manufacturers can pivot more easily, producing a wide variety of products without the need for extensive retooling or additional labour. In turn, this allows companies to be more responsive to market trends, capitalising on opportunities faster than their competitors.

Automation also enables the scaling of operations with greater ease. As demand for products increases, manufacturers can ramp up production by adding additional robots or automating more aspects of the production process. This scalability is essential for businesses looking to grow without the limitations imposed by traditional manufacturing methods.

5. Increased Safety for Workers

Manufacturing environments, particularly those involving heavy machinery or hazardous materials, can pose significant risks to human workers. Automation and robotics can help reduce these risks by taking on the more dangerous tasks. Robots can work in environments that are too hot, cold, or otherwise dangerous for humans, reducing the likelihood of workplace injuries.

For example, in chemical or heavy engineering industries, automated systems can handle toxic substances, lift heavy loads, or perform intricate tasks in confined spaces, minimising the exposure of human workers to these hazards. By improving workplace safety, manufacturers can reduce the costs associated with worker injuries, including compensation claims and downtime due to accidents.

In this way, automation not only protects workers but also enhances operational efficiency. With fewer accidents and injuries, manufacturing operations can continue without disruption, improving overall productivity and ensuring compliance with health and safety regulations.

Discover Robotics and Automation Courses

If you’re looking to develop your workforce in Automation and Robotics, then take a look at the courses we have on offer. The modular courses are designed to introduce learners to industrial robotic technologies and progress their technical skills to boost productivity.

Importantly, workers will be trained on ABB robots – the line also features an integrated Siemens PLC control system and a state-of-the-art dosing system, fully integrated in a Kyrus guarding enclosure.

- L3 1 Day Automated Cell Operator:

- L3 Programming of Robotics

- L3 Industrial Robot Technology

- L4 Automation, Robotics and Programmable Logic Controllers (PLCs)

View courses and book onto upcoming dates

Conclusion

The integration of automation and robotics into UK manufacturing is not just a technological trend—it is a necessity for businesses looking to thrive. The benefits are clear: increased productivity, improved quality, cost savings, and enhanced flexibility all contribute to a more efficient and competitive manufacturing sector. Furthermore, automation enhances worker safety and provides a buffer against labour shortages, ensuring the long-term sustainability of UK manufacturing. As the technology continues to evolve, the UK has the opportunity to lead the way in innovative, automated production methods, securing its place in the global manufacturing arena.

Follow us on our socials to stay up to date with industry news and updates from In-Comm Training!