TWP presses on with reshoring opportunity

A Black Country manufacturing specialist is looking to the next generation of engineers to help it deliver over £250,000 of new contracts recently repatriated from international rivals.

TWP Manufacturing, which employs 40 people at its expanding facility in Tipton, is looking to build on a 10-year relationship with In-Comm Training by taking on another apprentice to help it meet the surge in new orders.

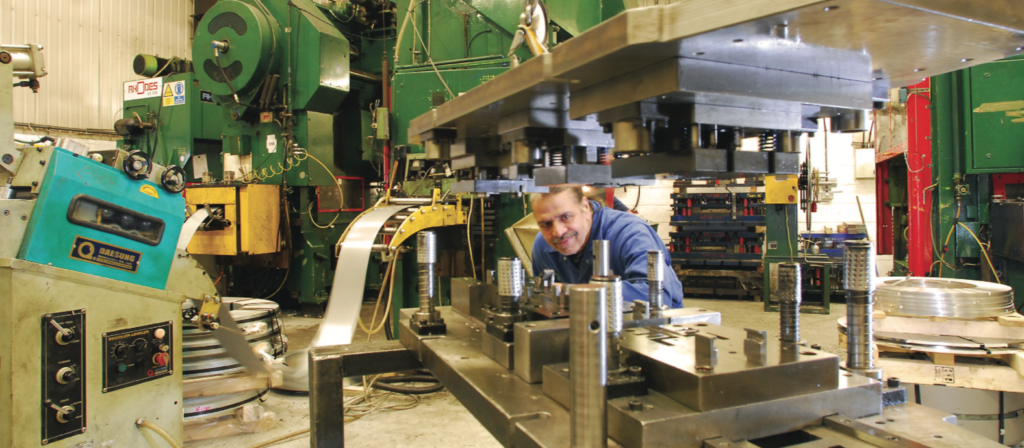

Specialising in high quality presswork and injection moulding, the business has been a long-term supporter of vocational learning and on the job training, recruiting nearly 20 people via this route since 2009 – some of whom have gone on to become Works Manager and Team Leaders.

It currently has one general engineering apprentice and is now looking for a second to help it set-up and maximise the recent investment in the CNC machine shop.

“We really like the flexibility of working with In-Comm Training,” explained Phil Stanley, Managing Director of TWP Manufacturing.

“As a SME, we can’t really afford to lose the young person for two days per week, so we have to come up with a course that gives them the competencies they need, but also immerses them into our workplace.”

He continued: “Then you’ve got the outstanding facilities the young people are learning on. We’ve just invested in ramping up our CNC workshop for some repatriation work and the fact that our apprentices can train on the latest software and 3, 4 and 5 axis machines is a major bonus.

“The facilities really are second to none and something we simply do not have the time to replicate as a manufacturer.”

TWP Manufacturing is a leading supplier of presswork, mouldings and assemblies to the automotive, construction, electrical and white goods sectors.

Its sister business – Paterson Photographic – also produces more than 16 different tripods and ancillary darkroom equipment for the photographic industry.

For further information, please visit www.threewaypressings.co.uk